目录

With advancements in technology, industrial laser cleaning has become an effective solution for manufacturers, particularly in the aerospace and automotive sectors. As demand for these machines grows, understanding the costs and benefits of laser cleaning is essential for businesses considering this investment.

How Industrial Laser Cleaning Works

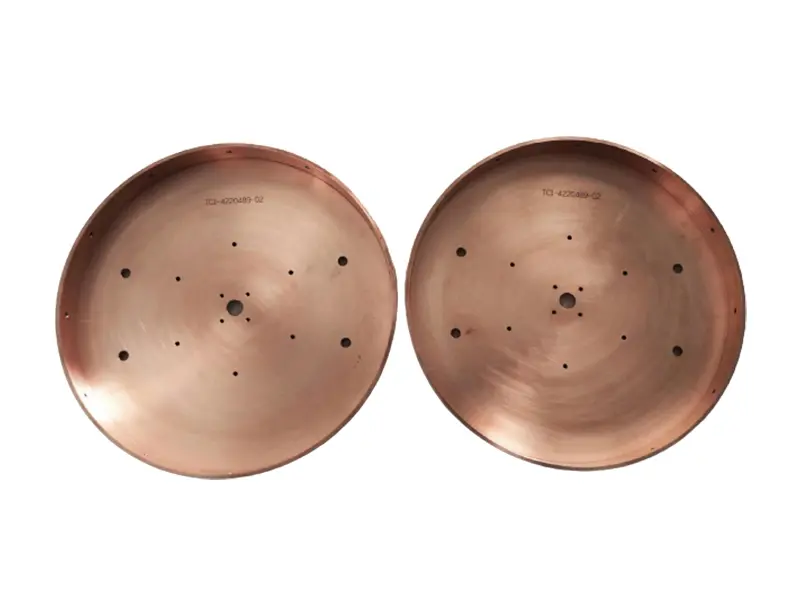

Industrial laser cleaning utilizes a pulsed laser to remove contaminants such as paint, rust, dust, and other residues from metal surfaces. This method is increasingly replacing traditional cleaning techniques. The machine emits thousands of laser pulses per second, which safely absorb and eliminate built-up contaminants without damaging the underlying material. Effective laser cleaning enhances equipment lifespan by preventing residue buildup that can hinder operation.

Advantages of Industrial Laser Cleaning

Laser cleaning offers several benefits, making it an appealing choice for various applications:

- Effective Contaminant Removal: It cleans surfaces without causing damage, making it suitable for delicate materials.

- Environmentally Friendly: This method captures hazardous materials like asbestos and lead paint, reducing waste and promoting a cleaner environment.

- Versatility: Laser cleaning is applicable for coating preparations, nuclear decontamination, welding, and surface preparation for non-destructive testing (NDI).

Disadvantages of Industrial Laser Cleaning

While there are many advantages, there are also potential downsides:

- Application Limitations: Laser cleaning is not ideal for all situations. For instance, in cases where grinding or media blasting is more effective, relying solely on lasers may not be beneficial.

- Selection of Equipment: Choosing the right laser product is crucial. Inappropriate choices can lead to ineffective cleaning or damage.

Safety Considerations

Industrial laser cleaning is generally safe when proper procedures are followed. Safety measures include the use of protective eyewear and establishing an optical hazard zone. For smaller applications, an enclosure may be necessary to ensure safety. Training in laser safety and operation is essential for users to minimize risks effectively.

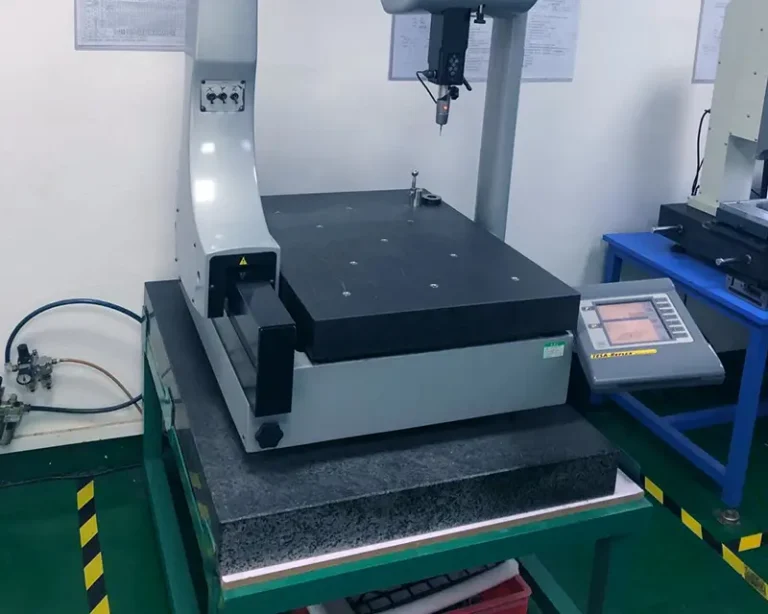

Choosing the Right Laser Solution

The best laser cleaning solution depends on various factors, including the type of contaminants, the materials involved, and the cleaning environment. Evaluating these aspects will help determine the most effective approach for your specific needs. It’s essential to select machines that have undergone thorough testing to ensure reliability and efficiency.

In conclusion, industrial laser cleaning presents a modern, efficient alternative to traditional cleaning methods. By understanding its mechanics, advantages, and potential limitations, businesses can make informed decisions about whether this technology aligns with their operational goals. With careful consideration of the type of laser solution needed, companies can achieve high-quality cleaning results while maintaining safety and environmental standards.

0