目录

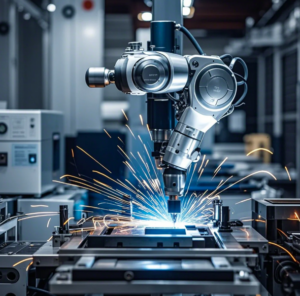

A 5 axis robot is an advanced robotic system designed to offer highly precise and efficient movement. Unlike traditional robots, which are limited to three axes of movement, the 5 axis robot can move in five different directions, providing greater flexibility and accuracy. In this article, we will explore the key functions, working principles, and applications of the 5 axis robot.

What is a 5 Axis Robot?

A 5 axis robot is a robotic arm that utilizes five independent axes of motion. These axes include three linear movements along the X, Y, and Z axes, and two rotational movements that allow the robot to change the orientation of its end effector or tool. This advanced movement capability enables the robot to perform highly complex and intricate tasks, such as precise cutting, drilling, and welding, which are often required in industries like aerospace and automotive manufacturing.

How Does a 5 Axis Robot Work?

The 5 axis robot operates by coordinating the motion of its five axes, allowing it to approach objects from various angles. The extra rotational axes give the robot more control over its end effector, enabling it to manipulate objects with greater precision. For instance, the robot can adjust its position and orientation simultaneously to handle complex tasks that would typically require multiple tools or machines. This coordinated movement provides superior accuracy and flexibility, which are essential for precision work in industries such as medical device manufacturing and 3D printing.

Applications of a 5 Axis Robot

The versatility of the 5 axis robot makes it ideal for various applications across different industries. In aerospace, it is used for assembling complex components with high precision. The automotive industry relies on 5 axis robots for tasks such as machining engine parts, assembling car bodies, and handling delicate components. Electronics manufacturers also use these robots for PCB assembly and component testing. Moreover, the 5 axis robot is increasingly employed in advanced fields like additive manufacturing (3D printing) and robotic surgery.

Benefits of a 5 Axis Robot

The main advantage of a 5-axis robot lies in its ability to perform tasks with high precision and at multiple angles. Its flexibility reduces the need for multiple setups or machines, making the production process more efficient and cost-effective. For example, a 5 axis robot can perform machining, cutting, and shaping operations while adjusting its position and orientation, which results in faster production times and improved accuracy. Its repeatability also ensures that tasks are completed consistently, making it invaluable in industries that demand high-quality output.

In conclusion, the 5 axis robot is a powerful tool in modern manufacturing, offering unmatched precision, flexibility, and efficiency. Whether in aerospace, automotive, electronics, or medical fields, the 5 axis robot is transforming production processes and setting new standards for automated tasks.

0