目录

The foundation of contemporary electronic gadgets is printed circuit boards (PCBs), which allow different components to connect and function together seamlessly. Placing electrical components onto a PCB board to produce a working circuit is an essential step in the electronics manufacturing process. In this blog, we will discuss what PCB assembly is, how it is done, what parts are involved, and why it is important in today’s tech-driven world.

What is the Assembly PCB Board?

The process of soldering and attaching resistors, capacitors, diodes, and integrated circuits (ICs) to a blank circuit board is known as PCB assembly or PCBA. The PCB is the physical board; however, electrical connections between the components and the circuit paths on the board are made possible during the assembly phase, which turns the PCB into a functional product.

The manufacture of PCBs involves two crucial stages:

- Making the bare board with copper lines and circuit paths is known as PCB manufacturing.

- PCB assembly is the process of assembling parts onto a board so that it can be utilized in electrical devices.

Methods of Assembly PCB Board

PCB boards are mostly assembled using two techniques, each tailored to a specific component or application.

- Surface Mount Technology (SMT):

SMT is currently the most widely utilized technique for PCB assembly. It entails putting tiny parts straight onto the board’s surface. Thanks to SMT, components can be mounted on both sides of the board, keeping the assembly small while enhancing the complexity and functionality of contemporary electronics. This approach is perfect for high-volume production because it is more automated and enables faster assembly times. - Through-Hole Technology (THT):

This conventional technique involves soldering components with leads or pins into pre-drilled holes on the PCB. THT is perfect for components that need extra stability or may be subjected to mechanical stress since it offers stronger physical connections. In contrast to SMT, it takes longer and is less widespread in today’s electronics manufacturing.

Key Steps in the Assembly PCB Board Process

Several meticulous procedures are involved in PCB board assembly to guarantee the finished result operates as intended:

- Solder Paste Application:

In surface mount assembly, solder paste is applied to the PCB’s designated mounting locations for components. This paste combines flux and microscopic solder particles to aid in the components’ adhesion to the board. - Pick-and-Place Procedure:

Automated pick-and-place machines precisely put surface-mounted components onto the PCB using the design layout as a guide. These devices can handle small components quickly and with extreme precision. - Soldering:

The components are soldered into place after being positioned on the board. - Inspection and Quality Control:

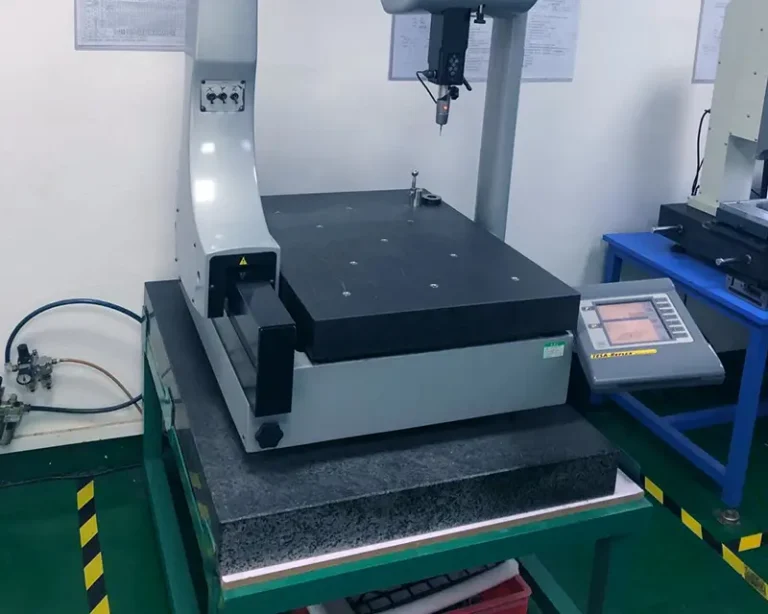

After assembly, the board undergoes various inspection processes to ensure quality and functionality.

Components Involved in Assembly PCB Board

- Resistors

- Capacitors

- Diodes

- Integrated Circuits (ICs)

- Transistors

- Connectors

Conclusion

Assembly of PCB boards is a vital process that transforms a simple circuit board into a functioning electronic device. Whether it’s for consumer electronics, automotive systems, or advanced medical equipment, PCB assembly enables innovation by connecting and powering the electronic components that make modern life possible.

0