目录

Selecting the right precision machining service provider is a critical step in ensuring the success of your project. As the manufacturing industry continues to demand higher levels of precision and efficiency, the capabilities and reliability of precision machining service providers have become increasingly important. Below are detailed steps and considerations to help you find the most suitable partner for your project.

Define Your Project Requirements

Before choosing a precision machining service provider, it is essential to clearly define your project requirements. This includes:

- Part Type: Are the parts you need to machine simple or complex? Do they require special materials, such as titanium alloys or composites?

- Precision Requirements: What are the specific tolerances and surface finish requirements for your project?

- Volume Needs: Do you require small-batch prototyping or large-scale production?

- Delivery Timeline: Does your project have strict delivery deadlines?

By clarifying these requirements, you can more effectively screen potential suppliers to ensure they meet your specific needs.

Evaluate the Provider’s Machining Capabilities

Precision machining services encompass a wide range of processes, including CNC milling, turning, grinding, and EDM (Electrical Discharge Machining). When selecting a provider, assess whether they have the following capabilities:

- Advanced Equipment: Do they have modern CNC machines and multi-axis machining equipment?

- Technical Diversity: Can they handle multiple machining processes to meet the needs of complex parts?

- Material Expertise: Do they have experience machining the materials you require? For example, the medical industry may need biocompatible materials, while the aerospace industry may require high-strength alloys.

Examine the Quality Control System

The core of precision machining services lies in accuracy and quality. Therefore, the provider’s quality control system is crucial. Key aspects to consider include:

- Certifications: Does the provider have international quality certifications such as ISO 9001? These certifications indicate that their quality management system meets global standards.

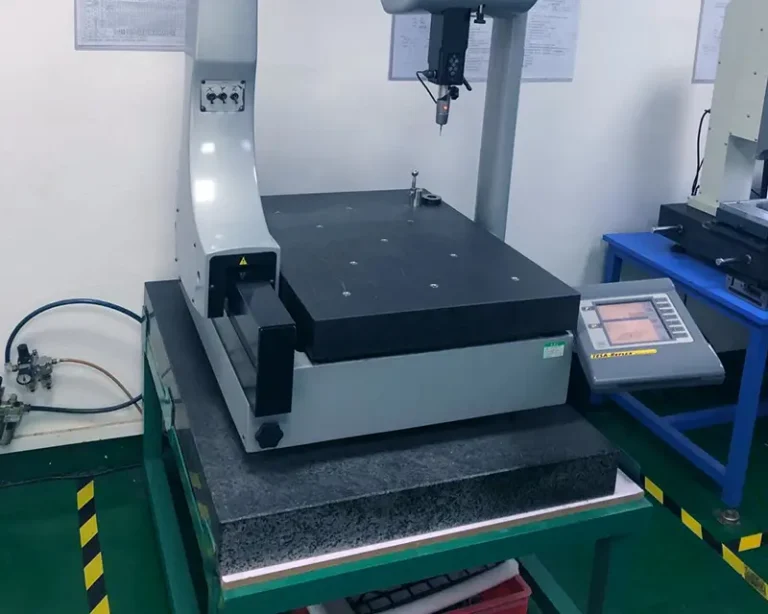

- Inspection Equipment: Are they equipped with high-precision inspection tools, such as CMM (Coordinate Measuring Machines) and optical measuring instruments?

- Quality Control Processes: Do they have strict quality control processes, including first-article inspection, in-process inspection, and final inspection?

Assess the Provider’s Industry Experience

Different industries have vastly different requirements for precision machining services. Choosing a provider with extensive experience in your industry ensures they understand your needs and can offer more specialized services. For example:

- Medical Industry: Requires high precision and expertise in machining biocompatible materials.

- Aerospace Industry: Requires the ability to handle high-strength materials and complex geometries.

- Automotive Industry: Requires large-scale production capabilities and high consistency.

By understanding the provider’s industry experience, you can better evaluate their suitability for your project.

Evaluate Production Capacity and Delivery Capabilities

The production capacity and delivery capabilities of a precision machining service provider directly impact your project timeline. Key aspects to consider include:

- Equipment Quantity: Does the provider have enough equipment to meet your production needs?

- Production Cycle: Can they complete the machining within your required timeframe?

- Flexibility: If project requirements change, can the provider quickly adjust their production plans?

Communication and Collaboration Skills

Effective communication is key to project success. When selecting a provider, assess their communication and collaboration capabilities:

- Responsiveness: Can they promptly respond to your inquiries and provide solutions?

- Technical Support: Do they offer technical support to help optimize your design and machining processes?

- Transparency: Are they willing to share production progress and quality data, ensuring you are fully informed about the project?

Cost and Value for Money

While cost should not be the sole deciding factor, it is an important consideration when choosing a precision machining service provider. Key aspects to evaluate include:

- Transparent Pricing: Does the provider offer a detailed quotation, clearly listing all costs?

- Additional Fees: Are there hidden fees, such as mold costs or shipping fees?

- Value for Money: Choose the provider that offers the best value while meeting quality and delivery requirements.

Review Customer Feedback and Case Studies

By reviewing customer feedback and success stories, you can gain a better understanding of the provider’s actual capabilities. Key aspects to consider include:

- Customer Reviews: What do their existing clients say about their services?

- Case Studies: Have they been involved in successful projects similar to yours?

- Industry Reputation: What is the provider’s reputation within the industry?

Conclusion

Choosing the right precision machining service provider for your project requires a comprehensive evaluation of multiple factors, including machining capabilities, quality control, industry experience, production capacity, communication skills, and cost. By systematically assessing and screening potential providers, you can find the most reliable partner to ensure your project is completed successfully and meets its objectives. Precision machining services are not just a part of the manufacturing process—they are a key driver of project success.

0