目录

Small Parts, Big Impact: Understanding the Role of precision CNC machining in Miniature Engineering

In the realm of modern manufacturing, the importance of small components cannot be understated. Miniature engineering, which deals with the production of tiny yet highly precise parts, relies heavily on precision CNC machining. This technology enables the creation of small, intricate components with exceptional accuracy and repeatability, playing a crucial role in various industries including medical devices, electronics, and aerospace. This article will delve into the role of precision CNC machining in miniature engineering, its applications, benefits, and the considerations necessary for maintaining high standards.

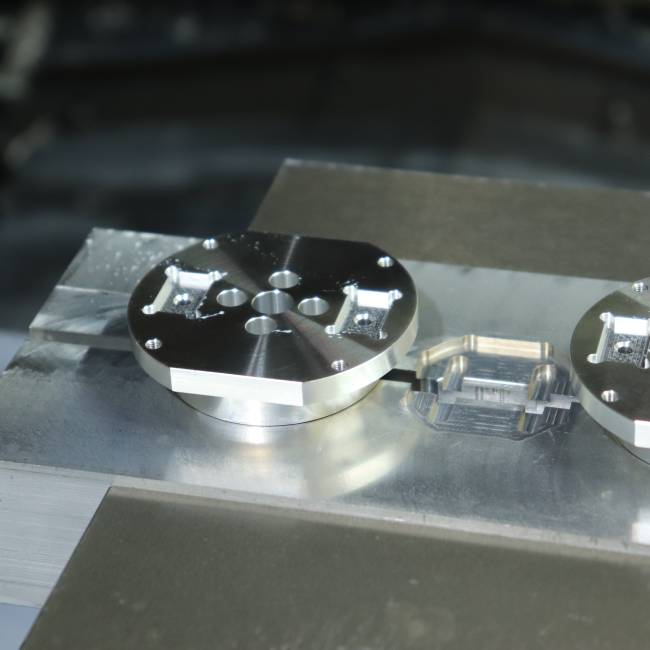

The Fundamentals of precision CNC machining

CNC (Computer Numerical Control) machining is a process where computer-controlled machines are used to manufacture parts with high precision. precision CNC machining takes this a step further by focusing on creating components with extremely tight tolerances and intricate geometries. This capability is essential in miniature engineering, where even the smallest deviation can lead to significant issues in the functionality of the final product.

Importance of precision CNC machining in Miniature Engineering

1. Accuracy and Precision:

– The primary advantage of precision CNC machining is its ability to produce parts with high accuracy. This is crucial in miniature engineering, where components often need to fit together perfectly in compact assemblies.

2. Repeatability:

– Precision CNC machining ensures that each part produced is identical to the last, which is vital for maintaining consistency in high-volume production runs.

3. Complex Geometries:

– The technology allows for the creation of complex shapes and features that would be impossible to achieve with traditional manufacturing methods.

4. Material Versatility:

– CNC machining can be used with a wide variety of materials, from metals to plastics, making it suitable for different applications within miniature engineering.

Applications of precision CNC machining in Miniature Engineering

1. Medical Devices:

– Components for medical devices such as pacemakers, insulin pumps, and surgical instruments require extreme precision. precision CNC machining is used to create these small, intricate parts that meet stringent regulatory standards.

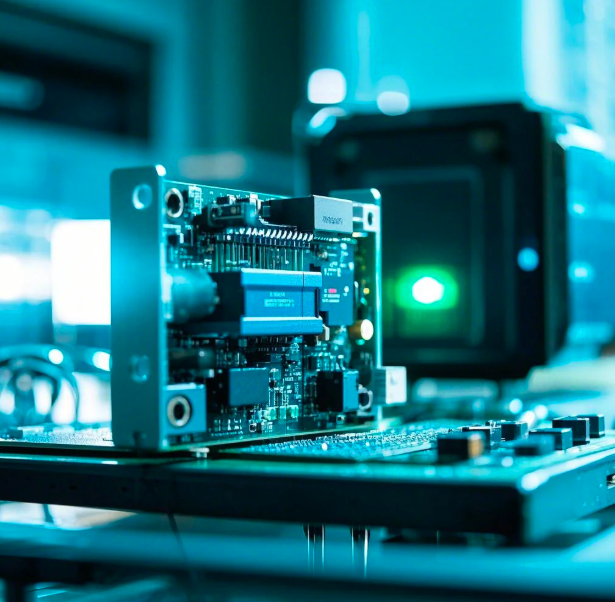

2. Electronics:

– The electronics industry benefits from precision CNC machining in the production of connectors, housings, and other small components that need to fit together seamlessly.

3. Aerospace:

– In aerospace, precision CNC machining is used to manufacture small parts that contribute to the overall performance and safety of aircraft and spacecraft. These include components in navigation systems, fuel controls, and sensor housings.

4. Watchmaking:

– The watchmaking industry relies on precision CNC machining to produce tiny gears, springs, and other components that require high accuracy to ensure proper timekeeping.

Benefits of precision CNC machining

1. Enhanced Performance:

– Parts produced through precision CNC machining often exhibit better performance due to their high accuracy and consistency.

2. Cost-Effectiveness:

– While the initial setup for CNC machining can be expensive, the high repeatability and reduced waste make it cost-effective for large production runs.

3. Reduced Lead Time:

– Precision CNC machining can significantly reduce lead times, allowing for quicker turnaround from design to production.

4. Quality Assurance:

– The precision and repeatability of CNC machining contribute to higher quality assurance, ensuring that every part meets the required specifications.

Considerations for precision CNC machining

1. Tooling and Equipment:

– The quality of the tooling and equipment used in CNC machining plays a significant role in the final product’s accuracy. Regular maintenance and calibration of machinery are essential.

2. Material Selection:

– Choosing the right material is crucial. Different materials respond differently to machining processes, and understanding these characteristics is important for achieving the desired results.

3. Design for Manufacturability (DFM):

– Designing parts with manufacturability in mind can help reduce production difficulties and improve overall efficiency. This includes considering factors like tolerances, surface finish, and complexity.

4. Inspection and Quality Control:

– Rigorous inspection and quality control processes are necessary to ensure that each part meets the required specifications. This can involve dimensional checks, surface finish inspections, and functional testing.

FAQ

Q: What are the key materials used in precision CNC machining for miniature parts?

A: Common materials include various metals like aluminum, titanium, and stainless steel, as well as plastics such as PEEK and Delrin. The choice of material depends on the application’s specific requirements, such as strength, weight, and corrosion resistance.

Q: How does precision CNC machining ensure high accuracy for small parts?

A: Precision CNC machining uses advanced computer control and high-quality tooling to achieve tight tolerances and intricate geometries. Regular calibration of machines and stringent quality control measures further ensure high accuracy.

Q: What industries benefit most from precision CNC machining in miniature engineering?

A: Industries such as medical devices, electronics, aerospace, and watchmaking benefit significantly from precision CNC machining due to the need for highly accurate and reliable small parts.

Q: How can lead times be reduced in precision CNC machining?

A: Lead times can be reduced through efficient design practices, the use of high-speed machining techniques, and maintaining a streamlined production process. Advanced CNC machines with rapid tool change capabilities also contribute to faster production cycles.

Precision CNC machining is indispensable in miniature engineering, enabling the production of highly accurate and complex small parts. Its role in various industries underscores its importance in modern manufacturing, ensuring that even the tiniest components can have a significant impact.

0

.webp)